the load applied in c-scale of rockwell hardness test is|rockwell hardness testing definition : retailer The determination of the Rockwell hardness of a material involves . Braquage du casino. Braquage du casino. Réserver sur le site de l'escape game. Escape games > . Alors, quel sera votre plan d'action pour parvenir à déjouer toutes les caméras, cadenas et mots de passe du coffre fort du The Game Casino Royal ? . Restez informé des dernières actualités Escape Games dans votre région !

{plog:ftitle_list}

O jogo anterior do San Marino foi contra o Finland pelo European Championship, Qualification, o jogo terminou com o resultado 1 - 2 (Finland ganhou o . Ver mais

A Rockwell C scale test on hardened steel, for example, penetrates to a depth of approximately 0.0035 inch, with the diameter of the indentation only 0.019 inch, which is barely visible. The .Preliminary test loads (preloads) range from 3 kgf (used in the “Superficial” Rockwell scale) to 10 kgf (used in the “Regular” Rockwell scale). Total test forces range from 15kgf to 150 kgf (superficial and regular) to 500 to 3000 kgf . The determination of the Rockwell hardness of a material involves .In hardness testing according to Rockwell, the total test force is applied in two steps. This is intended to eliminate effects from the roughness of the specimen surface (e.g., grooves on the specimen) as well as measurement errors .

The Rockwell hardness test is the industry standard measuring system used to determine how resistant a material is to another object. Hardness is defined as a material’s resistance to permanent indentation. This test was .The Rockwell hardness test utilizes 1 of 6 different main loads: In total, this gives 30 different Rockwell scales. Each one is characterized by a different combination of indenter type and main load, and is suitable for a particular . The various indenter varieties and range of test loads form a matrix of Rockwell hardness scales, which can be applied to a wide range of materials. Every Rockwell hardness scale is identified by a letter signifying .There are two general classes of Rockwell test: Rockwell and superficial Rockwell. In Rockwell testing, the minor load is 10 kgf and the major load is 60, 100 or 150 kgf.

The Rockwell hardness test measures the depth of penetra-tion of an indenter into a material under a known load. It provides a hardness value based on the depth of penetration. 2 Brinell .

The Vickers hardness test can be applied for micro-testing. Knoop: . Hardness Testing Loads. The hardness testing load is the load (“force”) that is applied to the indenter when pressing into the material being .Definition of the Rockwell hardness test method The Rockwell hardness test methods are described by a number of scales, characterized by a standard, an indenter type, and a load. Examples of Rockwell hardness test methods: .Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find .The article helps you understand principle and applications of the Rockwell hardness test method. + 86 755 61301520; [email protected] . and the combination of initial minor loads and final major loads also distinguishes the Rockwell method from other test methods. The applied load ranges from 15kgf to 150kgf, where a 3kgf is usually .

gas spring wont compress

Explanation: Most widely used hardness test is a Rockwell test in the US. It is because of the fast speed. It gives a small indentation. 2. Rockwell test utilizes _____ a measure of hardness. . Hardened steel is a very hard material. So it is tested by the diamond indenter. On C scale, the load of 150 kg is applied. advertisement. 8. Which .

This first load is removed, and another heavier load is applied to the indenter on the test piece. The Rockwell hardness of the test piece is calculated by subtracting the second load from the first and using the Rockwell formula. The resulting value is then translated to the Rockwell C scale of hardness to determine the hardness of the material.Load: The Rockwell hardness test uses a pre-load of 10 kgf, followed by the application of the main load, which varies depending on the Rockwell scale being used (e.g., 60 kgf for the Rockwell A scale, 150 kgf for the Rockwell C scale). The load is .Scale C (carbide) testers are used for testing cemented carbides in the Rockwell A Scale, where tolerances of ± 0.20 of a Rockwell Hardness point are required. A specially selected “A” Brale penetrator is used to measure the hardness of cemented carbides in accordance with ASTM B 294 and the Cemented Carbide Producer’s Association (CCPA).Regular Rockwell Hardness Test where the minor load is 10 kgf and major load is 60, 100, or 150 kgf. Superficial Rockwell Hardness Test where the applied minor load is 3 kgf and the major loads are 15, 30, or 45 kgf.

Hardness Testing. G. Sundararajan, M. Roy, in Encyclopedia of Materials: Science and Technology, 2001 1.1 Rockwell Hardness Testing. In a Rockwell hardness test, initially a minor load of 10 N is applied and the zero datum position is established. The major load (60, 100, or 150 N) is then applied for a specific period (a few seconds) and removed, leaving the .

Variants on the Rockwell hardness test procedure are used depending on the material and strength of a part. The most common Rockwell variants include: . HRC – Known as “Rockwell C,” a 150 kgf load is applied via a diamond in this method. . They also state the correct scale and call out the correct load and testing medium to be used. There are two types of Rockwell test (Table 23.1): Rockwell: the minor load is 10 kgf, the major load is 60, 100, or 150 kgf. Superficial Rockwell: the minor load is 3 kgf and major loads are 15, 30, or 45 kgf. Table 23.1: Some common scales in Rockwell and Superficial Rockwell testing The minor load of 10 KGS is applied first. Remove the major load turning the handwheel back until the indicator hand is in position “set” on the dial. . The equation for the Rockwell hardness test for metals is below: d=depth from zero load point. N and s = various scale factors that can be found in the chart below. Rockwell A scale. Used .

At first, a preliminary test force (preload or minor load) is applied upon the sample with the help of a diamond or ball indenter. This preload breaks through the surface to decrease the effects of surface finish. . Additionally, metals have A, B, C, and F as the popular Rockwell hardness scales, while polymers use M and R scales. Superficial . Once you have this information, you can use the following steps to calculate the Rockwell hardness value: Determine the Rockwell scale: The Rockwell scale is determined by the load applied and the type of indenter .

The Rockwell hardness scale is designed to determine the hardness of materials like aluminum, thin steel, lead, iron, titanium, copper alloys, and cemented carbides. . This is called as an indent and its depth is measured. . Brinell hardness test is an indentation hardness test.It uses a hard spherical ball (usually around 10mm in diameter). An applied force (a typical test will use 3,000 kilograms) pushes the ball against the surface of the .

C. When testing on the Rockwell B scale, if the HR value of an indentation exceeds 100 points, change the indenter ball. Make one indentation on a test block to seat the indenter and continue the measurement series on the specimen. If additional HR values in the test series exceed 100 points, a different scale will be used (e.g. Rockwell C scale).There are two types of Rockwell test (Table 23.1): Rockwell: the minor load is 10 kgf, the major load is 60, 100, or 150 kgf. Superficial Rockwell: the minor load is 3 kgf and major loads are 15, 30, or 45 kgf. Table 23.1: Some common scales in Rockwell and Superficial Rockwell testingmechanism to ensure that the load is applied gradually. 7. As soon as the pointer comes to rest pull the handle in the reverse . Applications of Rockwell Hardness A ± Scale, B-Scale, C-Scale. 3. Type of Indentor used in the Three Different Scales of Rockwell Hardness . Selection of Load in Rockwell Hardness Test. AUROR $¶67(&+12/2*,&$/ .

II. Theory and Principle of the Rockwell Hardness Test. The Rockwell Hardness Test uses a depth-differential method to test for hardness. A predetermined minor load is applied to the test sample, and the depth measurement is taken. Then a major load is applied to the same spot, which creates a deeper indentation. The hardness reading represents the additional depth of penetration beyond the minor load. Tester accuracy is checked by running the test on specimens whose hardness has been certified by an independent testing laboratory. All Ames hardness testers perform genuine Rockwell Hardness tests, giving a direct Rockwell reading. Their accuracy meets .International Standards Organization – Rockwell Hardness Test Part 1 – Test Method (ISO 6508-1 Metallic Materials) The reason all steel product manufacturers use the Rockwell hardness scale is that it allows uniformity in reporting test results. Everyone in the steel industry recognizes the Rockwell hardness scale.

A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter .Rockwell Hardness Testing: Measures the permanent depth of indentation; Brinell Hardness Testing: Involves applying a known load to the surface of the test sample via a hardened steel or carbide ball; Vickers Hardness Testing: Utilises an optical measuring system to measure the area of the impression

Hardness Testing. G. Sundararajan, M. Roy, in Encyclopedia of Materials: Science and Technology, 2001 1 Macrohardness Testing 1.1 Rockwell Hardness Testing. In a Rockwell hardness test, initially a minor load of 10 N is applied and the zero datum position is established.The major load (60, 100, or 150 N) is then applied for a specific period (a few . Figure 1 reflects common Rockwell scales used and their corresponding major loads. Figure 1. When Rockwell hardness testing, a minor load of 10kg is applied to the indenter used on the material being tested. The purpose of the minor load is to penetrate the material’s surface and establish a set position. After the minor load is applied, the .

10 inch springlift gas springs 6 3 4 compressed

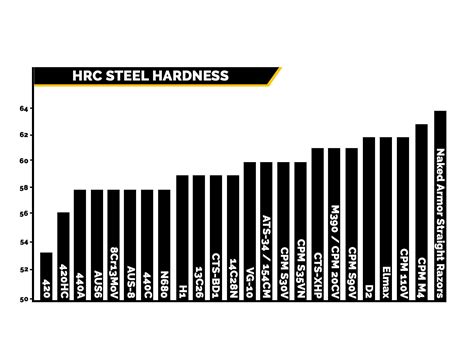

rockwell steel hardness scale

Sobre Medusa II. No jogo de slot Medusa II, você explora as ruínas antigas de Atenas, agora contaminadas por uma presença maligna. Jogue como o guerreiro grego Perseus .

the load applied in c-scale of rockwell hardness test is|rockwell hardness testing definition